Inprentus Precision Optics, the worldleader in custom mechanically-ruled blazed diffraction gratings, adds Metrology Services to its product offerings

CHAMPAIGN, IL, UNITED STATES, April 5, 2024 / https://www.einpresswire.com/article/701260558/inprentus-launches-diffraction-grating-metrology-services

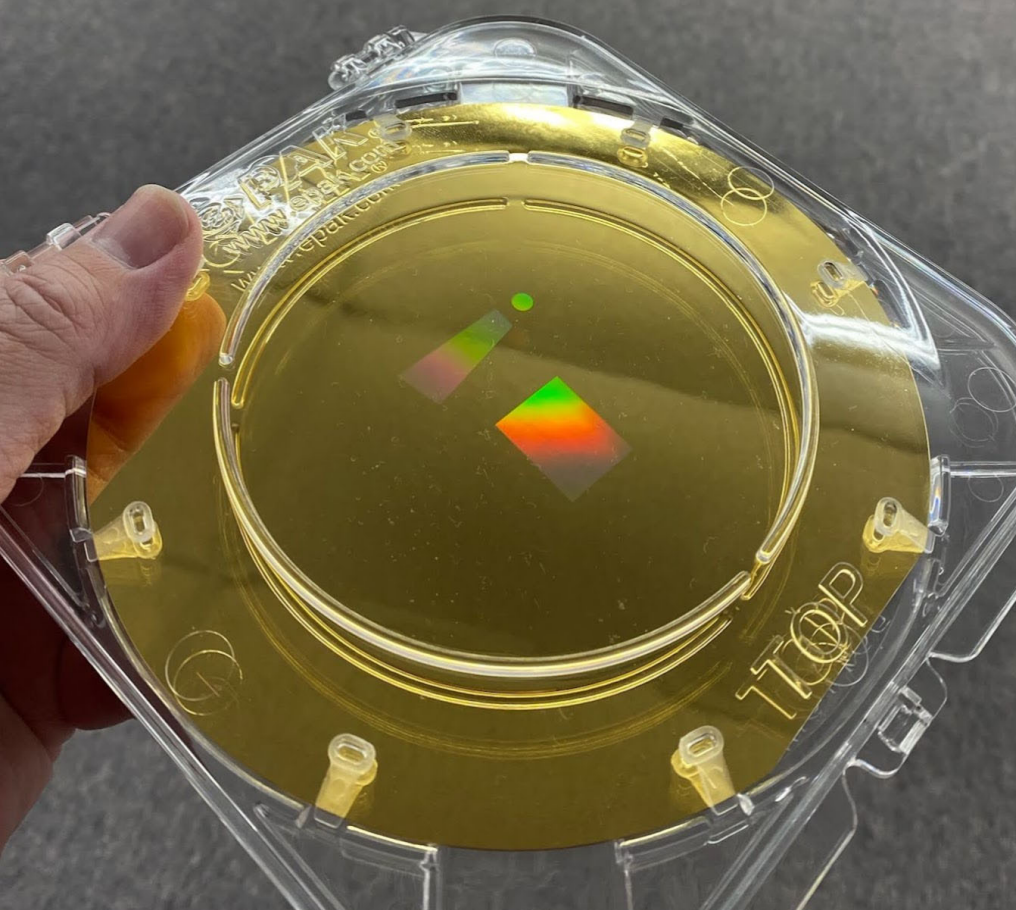

Inprentus Precision Optics, the world leader in custom mechanically-ruled blazed diffraction gratings, has announced the addition of Metrology Services to its product offerings. Founded in 2012, Inprentus specializes in the manufacture of Blazed Gratings for Synchrotrons, Free Electron Lasers, Spectroscopy, EUV, Semi-Conductors, and Augmented Reality Waveguides. With the addition of Metrology Services, Inprentus now offers their unique expertise to serve customers through all phases of optical services – from design to manufacture to characterization. With over 10 years of experience in assessing key properties to benchmark grating performance, Inprentus has deep subject matter expertise stemming from first principles of optics. Inprentus' metrology offerings include:

• Fizeau Interferometry to measure resolving power

• Atomic Force Microscopy (AFM) to measure groove shape, dimensions, and surface roughness

• Focused Ion Bean (FIB) and Scanning Electron Microscopy (SEM) to measure groove shapes

• Two-Circle Diffractometer to measure blaze and anti-blaze angles for the whole grating

• Two-Circle Diffractometer to measure stray light for both angle integrated and angle resolved modes

• 248nm Reflectometer to measure grating efficiency

• Custom metrology projects (contact Inprentus)

Subha Kumar, Inprentus' Chief Growth Officer, explained that “Following our founder Peter Abbamonte’s presentation at SPIEXR 2024 highlighting the large variety of grating-specific measurements we routinely use, it was clear that there was substantial industry interest in our unique metrology capabilities. We are excited to respond to the call to share our deep grating expertise and to continue to create the world’s most advanced diffractive optics.”

About Inprentus

Inprentus was founded in 2012 to commercialize an innovative, dual atomic force microscope scribing technology, used to carry out nano-scale lithography via mechanical deformation of metallic surfaces. Inprentus designs, manufactures, and characterizes diffraction gratings for use in research facilities, manufacturing, and augmented reality. Contact Inprentus at info@inprentus.com to start your next grating project!

Subha Kumar

Inprentus, Inc

+1 217-239-9862

This press release can be viewed online at: https://www.einpresswire.com/article/701260558