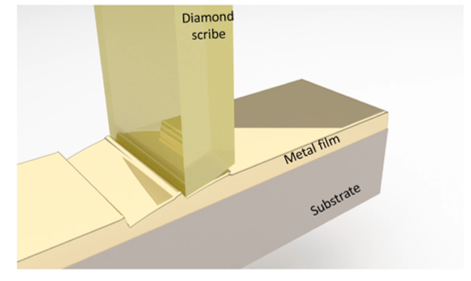

Technology: Mechanical Ruling

A precision tool shapes metal into triangular facets. No material is removed, and one line is ruled at a time. Inprentus can rule 15,000 lines a day in an automated fashion.

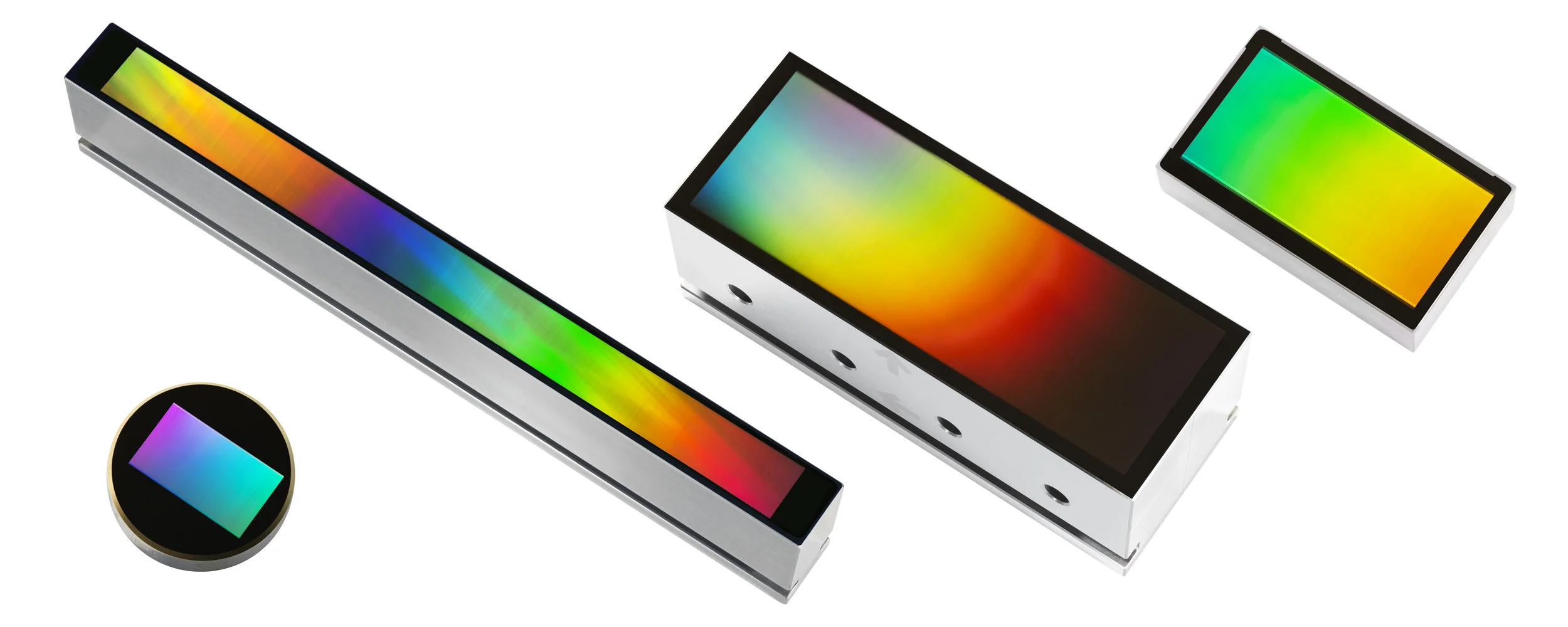

Inprentus manufactures blazed, x-ray diffraction gratings using a novel nano-scale contact mode lithography technique (mechanical ruling) that can scribe thousands of lines per millimeter, providing the ultra-accuracy required for diffraction gratings used in a variety of applications. Inprentus can scribe grating lines with blaze angles below 1 degree with an accuracy of 0.1 degree or better, without the need for ion-milling or other post-processing. Novel interferometry techniques developed at Inprentus allow for grating lines to be positioned with accuracy better than 20 nm over distances of 10 cm or larger. Using this technology, Inprentus creates gratings with resolving power up to 50,000, unprecedented for mechanically ruled diffraction gratings. Inprentus diffraction gratings are a core component of augmented reality (AR) applications, semiconductor manufacturing, and in materials, chemistry, and life sciences research.

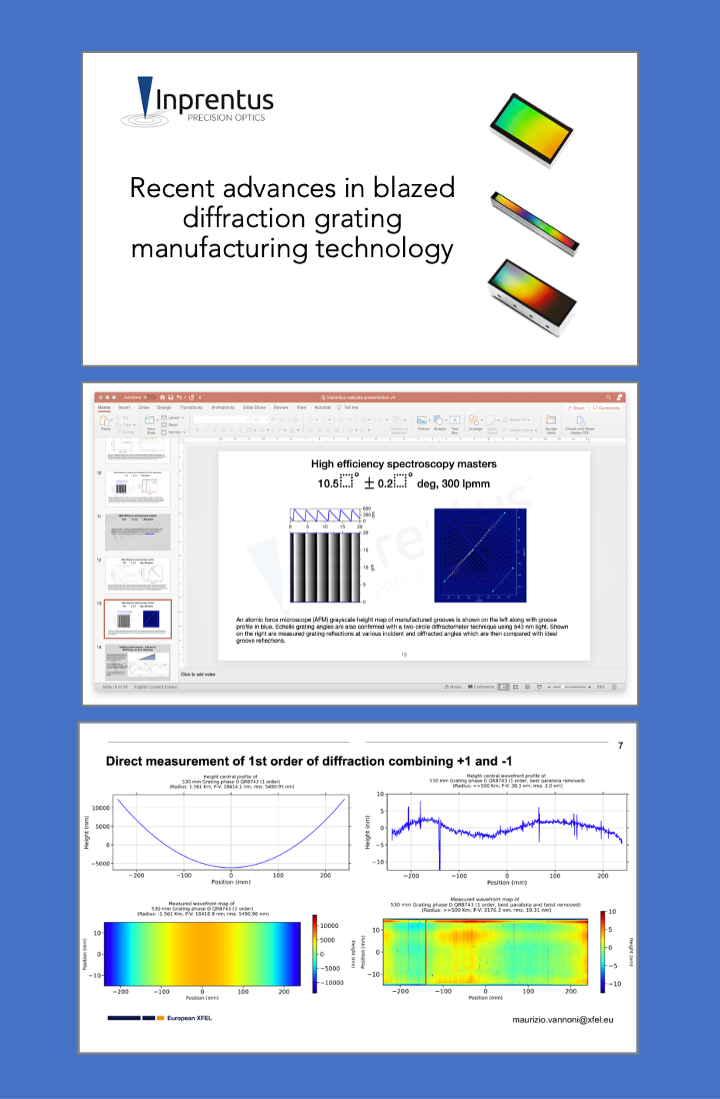

Presentation: Recent advances in blazed diffraction grating manufacturing technology for synchrotron, FEL, EUV, and spectroscopy applications